Installation and Maintenance of Wire Mesh Demister Pads

Nowadays, wire mesh demisters are widely used in many environmental protection projects. They are low in cost, easy to install, and most importantly, very effective in removing mist.

Wire Mesh Demisters Installation Methods

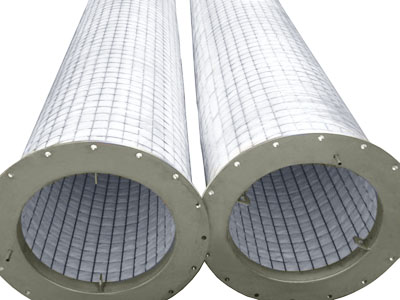

Wire mesh demisters can be installed in two ways: upload demister pads and download demister pads.

Upload demister pads: If the manhole is above the demister, or if there is no manhole but a flange exists, the demister is installed from the top.

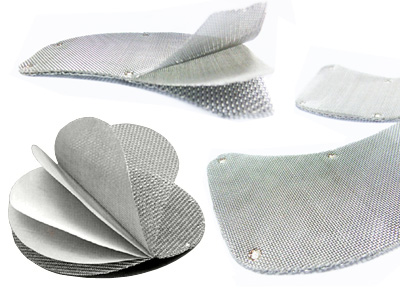

Download demister pads: If the manhole is below the demister, the mesh blocks are passed through the bottom manhole and placed one by one on the support device inside the tower.

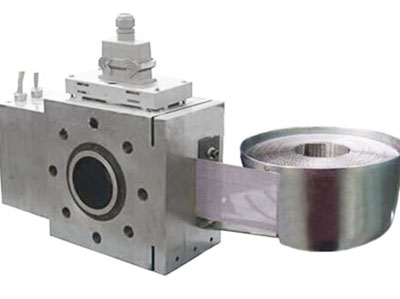

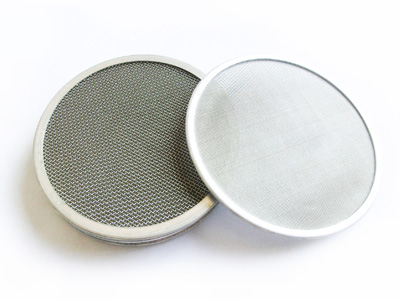

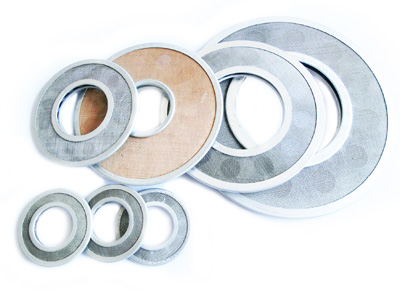

For demisters with diameters from DN300 to DN1600mm, the size is small and weight is light. The mesh blocks do not need to be cut in the middle. In this case, the support structure is simple,just place support grids of the same diameter above and below the demister.

The performance of a bottom-installed demister depends on the quality of the mesh pad manufacturing and installation.

The mesh pad must meet these requirements:

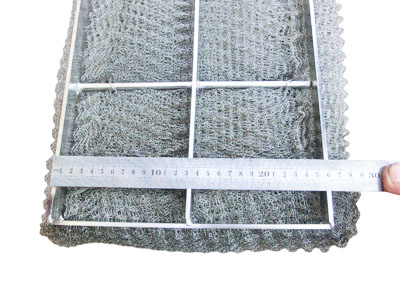

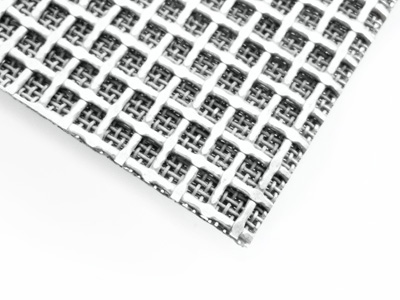

The mesh is woven from flat wire or round wire, and then pressed into a corrugated knitted wire mesh.

The mesh pad can be rolled or laid flat. Flat, cross-stacked layers give the best separation efficiency.

To prevent gas from bypassing between the mesh pad and the inner diameter of the tower, the mesh pad diameter must be slightly larger than the inner diameter of the tower.

Wire Mesh Demisters Simple Maintenance

After some time in operation, particles in the gas may block the mesh, causing liquid flooding and higher pressure drop. Therefore, the demister should be maintained depending on its working condition.

If the equipment is out of service for a long period, air can enter the tower. Moisture in the air may react with acid mist remaining in the mesh, forming dilute acid. Since wire mesh is usually not resistant to dilute acid, the demister should be removed for maintenance.

The normal method is to wash it with clean water.

After washing, the mesh pad must be dried either by heating or natural sunlight to prevent acid formation that can shorten its lifespan.

Once completely dry, it can be re-installed before the next startup.